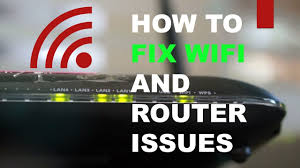

How to Reset Your Router and Fix Internet Connectivity Issues

In today’s digital age, a stable internet connection is crucial for work, entertainment, and communication. Unfortunately, network interruptions can happen at any time. Learning how to fix internet connectivity issues is essential for minimizing downtime and ensuring a smooth online experience. One of the most common and effective solutions is to reset your router. This guide will walk you through step-by-step procedures, tips, and troubleshooting strategies to restore your internet connection efficiently.

Why Your Internet Connection May Fail

There are multiple reasons why your internet might be acting up. Understanding these can help you determine the best course of action:

-

Router Glitches – Over time, routers can experience firmware glitches that affect performance.

-

ISP Problems – Sometimes, the issue is on your internet service provider’s end.

-

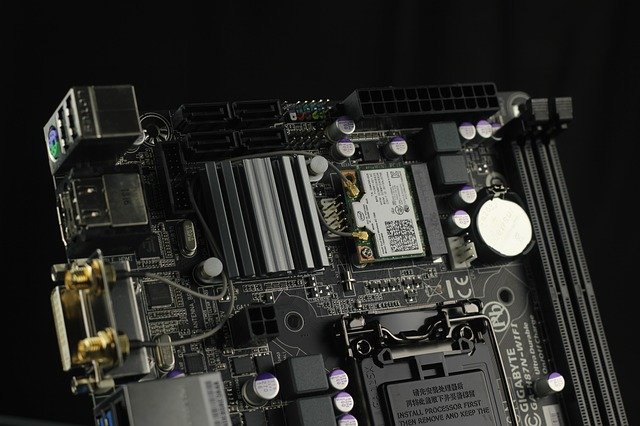

Hardware Failures – Damaged cables, outdated routers, or worn-out components can cause intermittent connections.

-

Overloaded Network – Multiple devices streaming or downloading simultaneously can slow or interrupt service.

-

Interference – Wireless signals can be affected by other electronics or structural barriers in your home.

Recognizing these factors allows you to troubleshoot effectively and decide when to reset your router.

Step-by-Step Guide to Reset Your Router

Resetting your router is often the quickest way to resolve connectivity issues. Here’s how to do it safely:

1. Soft Reset

A soft reset is a simple restart of your router and is usually enough to resolve minor glitches.

-

Turn off your router using the power button.

-

Wait for 30 seconds to 1 minute.

-

Turn the router back on.

-

Wait until all indicator lights stabilize.

This process refreshes the router’s memory and clears minor software errors without erasing your settings.

2. Hard Reset

A hard reset restores your router to factory settings and should be used when persistent issues occur.

-

Locate the reset button on your router (usually a small pinhole).

-

Use a paperclip or pointed object to press and hold the reset button for 10–30 seconds.

-

Release the button and wait for the router to reboot completely.

-

Reconfigure your Wi-Fi network settings, as all previous configurations will be lost.

Tip: Always keep your ISP credentials handy before performing a hard reset.

3. Reboot Your Modem

Sometimes, the modem may be the source of the issue. To reboot:

-

Turn off the modem.

-

Disconnect the power cable.

-

Wait 1–2 minutes and reconnect.

-

Turn the modem back on and verify the connection.

Rebooting the modem can resolve issues related to your internet provider.

Troubleshooting Additional Connectivity Problems

Even after resetting, some issues may persist. Here’s how to tackle them:

1. Check Cable Connections

Loose or damaged cables can interrupt your network. Ensure:

-

Ethernet cables are securely connected.

-

Power cords are intact and properly plugged in.

-

No visible signs of wear or damage.

2. Update Router Firmware

Manufacturers regularly release firmware updates to improve performance and security.

-

Access your router’s admin panel.

-

Navigate to the firmware or system update section.

-

Download and install the latest firmware version.

Updating firmware can prevent future connectivity issues.

3. Optimize Wi-Fi Settings

Wireless interference is a common problem. Steps to improve Wi-Fi:

-

Change your router’s channel to avoid overlapping with neighbors.

-

Position your router centrally in your home.

-

Minimize obstacles such as walls or appliances.

-

Consider using dual-band routers for better coverage

4. Limit Device Overload

High traffic can overwhelm your router.

-

Disconnect unused devices.

-

Schedule heavy downloads during off-peak hours.

-

Use Quality of Service (QoS) settings to prioritize essential traffic.

5. Check for Malware or Viruses

Sometimes, a slow internet connection isn’t the router’s fault. Devices infected with malware can consume bandwidth.

-

Run a complete antivirus scan.

-

Update your system security patches.

-

Disconnect compromised devices from the network.

Best Practices to Prevent Future Internet Issues

Preventing connectivity problems is easier than fixing them. Follow these tips:

-

Regular Router Maintenance – Restart your router weekly.

-

Secure Your Network – Use strong passwords to prevent unauthorized access.

-

Monitor Network Traffic – Use apps or software to track usage.

-

Keep Firmware Updated – Regular updates prevent performance drops.

-

Invest in a Quality Router – High-performance routers handle multiple devices efficiently.

When to Contact Your ISP

If you’ve tried all troubleshooting steps and still face connectivity problems:

-

Call your ISP to check for service outages in your area.

-

Ask for guidance on router compatibility.

-

Request a technician visit if hardware issues are suspected.

Your ISP can often detect problems beyond your control and offer solutions.

Comparing Router Types

Different routers suit different needs:

| Router Type | Pros | Cons | Best For |

|---|---|---|---|

| Single-Band | Affordable, easy setup | Limited range | Small homes |

| Dual-Band | Better range, reduces interference | More expensive | Medium homes, multiple devices |

| Mesh Network | Covers large areas, seamless roaming | High cost | Large homes, heavy usage |

Choosing the right router enhances network stability and reduces the need to frequently reset your router.

Conclusion

Maintaining a stable internet connection is essential in today’s connected world. By knowing how to fix internet connectivity issues and reset your router, you can quickly restore your network and avoid prolonged downtime. Regular maintenance, firmware updates, and proper router placement also contribute to a smooth and reliable connection. Following these strategies ensures you can enjoy uninterrupted browsing, streaming, and working from home.

FAQ Section

1. How often should I reset my router?

Resetting once a month or when connectivity issues arise is sufficient. Frequent resets may indicate a hardware problem.

2. Will resetting my router delete my Wi-Fi password?

A soft reset won’t, but a hard reset will erase all settings including your password.

3. My router still drops connection after resetting. What should I do?

Check cables, update firmware, optimize Wi-Fi settings, or contact your ISP if issues persist.

4. Can malware affect my internet connectivity?

Yes, malware can consume bandwidth and disrupt network performance. Run antivirus scans regularly.

5. Is it safe to reset a modem along with a router?

Yes, rebooting both devices can resolve many connectivity problems and is recommended if a single reset doesn’t work.